A contractor was lucky to escape serious head injuries whilst maintenance work was being carried out on a conveyor belt system, a metal return roller guard fell 4m and hit his hard hat.

Hard hat with dent along back near centre

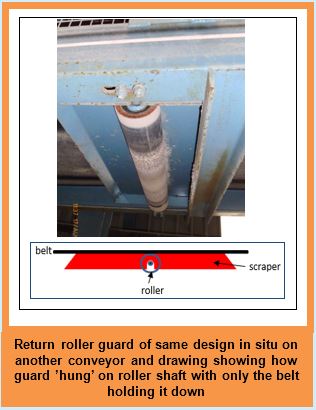

The contractor was standing under the incline conveyor belt system as he pulled the old conveyor belt through the system. During this operation an original return roller nip guard was dislodged. Investigation showed that it was designed so that it hung over the roller shaft and was only held in place by the belt and gravity.

The guard weighing circa 8kg fell 4m and hit the contractor on the centre of his hard hat. Fortunately, the contractor suffered only neck and muscle strain and was able to continue working after a short period.

This design may exist on conveyor systems on other sites.

LEARNING POINTS / ACTIONS TAKEN

- Check to see if this type of system is present on your site

- If they are on site, amend risk assessments / safe systems of work to include the need to check how roller nip guards, rollers and scrapers are secured

- Ensure all return roller nip guards, rollers and scrapers are securely fixed before any conveyor belt replacement work commences

- Any person carrying out a task where objects or items above them could fall should wear a hard hat, not a bump hat.

- Exclusion zones should be set up in any area where equipment is being worked on overhead